Hmmm - maybe I've been doing this without realizing it? Have you seen some of my sessions?

Truth to tell, no, I haven't. But examining these I note examples of the three very, very large related differences between most of the operating I see in TRS, and the prototype in North America [NB: My comments may reflect operations in other areas of the world, too, but I have no particular basis for knowing for sure whether they do or do not]. First, it takes a considerable amount of time to load and unload a car--an hour per car is a good starting point, and it is often longer than that, sometimes much longer. I have recently seen a car which took six _weeks_ to unload! The second difference is a predicate to the amount of time required to load and unload: "live loading" is extremely rare. I can think of a single class of examples in the U.S.: unit coal trains are "live loaded", but they are not operated by railroad personnel, but by employees of the mine. The third difference is that with a few exceptions, shippers and consignees are considerably further apart than they are in most TRS. So, in the first session, the "nine [empty] white Procor tank cars" would be dropped for loading on one day, and in a later session, when loaded, be picked up land distributed. Further the rail crew has no discretion of over which car goes to which consignee, so instead of "three at fingers foundry", (assuming for the sake of discussion that the cars are PROX 1-9) the crew will be directed to leave PROX 1, 3, and 7 at the foundry. Similary, the cars to be pulled from each industry would be specifically identified by proper initials and car number.

An additional note, about the first session you cite: in the U.S. because of a number of spectacular, but tragic accidents involving certain types of commodities, there are specific laws regarding the handling of many types of commodities. You don't specify in the session dialog exactly what commodity is being loaded in the tank cars, but odds are very high that the commodity being loaded at a Petrochem plant, is one which the regulations require be placed in a train no closer than six cars from the locomotive.

Charlie and Harry might well take the flats loaded with pipes, and the intermodal equipment to the specified locations, but rather than being instructed to unload the equipment, they would be instructed to drop the equipment for unloading, and to pick up equipment they (or another crew) had dropped at those facilities earlier that was already loaded (or empty) and set to go.

My comments may or may not apply to Kurt and Steffan, the "Achtung" suggests to me that they are operating in Germany in prior years, and I am not sufficiently familiar with their environment to comment on that session.

My comments here should not be interpreted as meaning that there is anything wrong, or defective with your sessions, or with the operations model used by most model railroaders, both virtual and tangible. Not only is it the way model railroaders have been operating for many years, and so is validated by the culture of model railroading, but more importantly, your model railroad is in your world, of which you are the master. You can operate it any way you choose, and I won't criticize. However, my preference is to operate my railroad in a manner which more closely reflects how things generally happen in the real world.

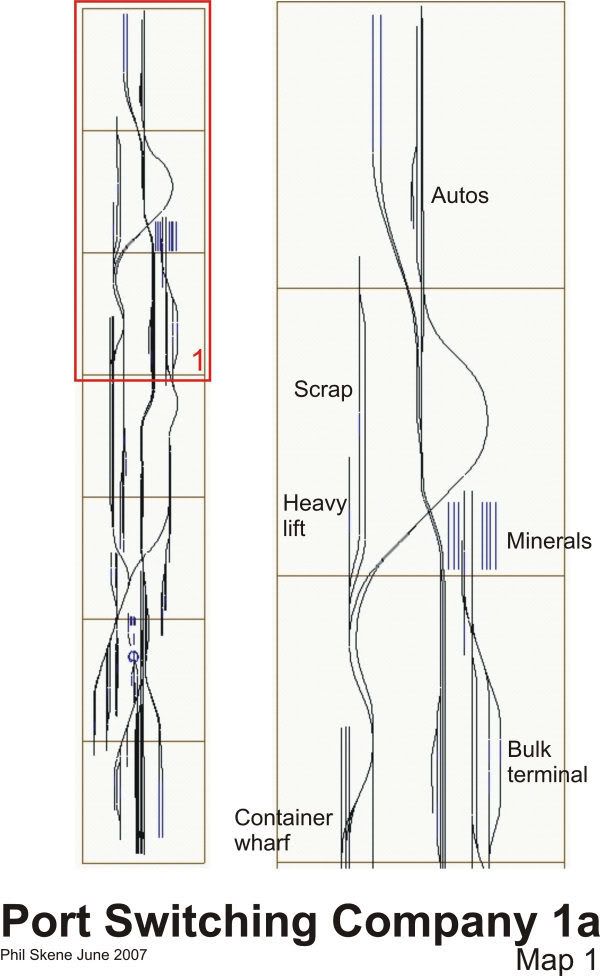

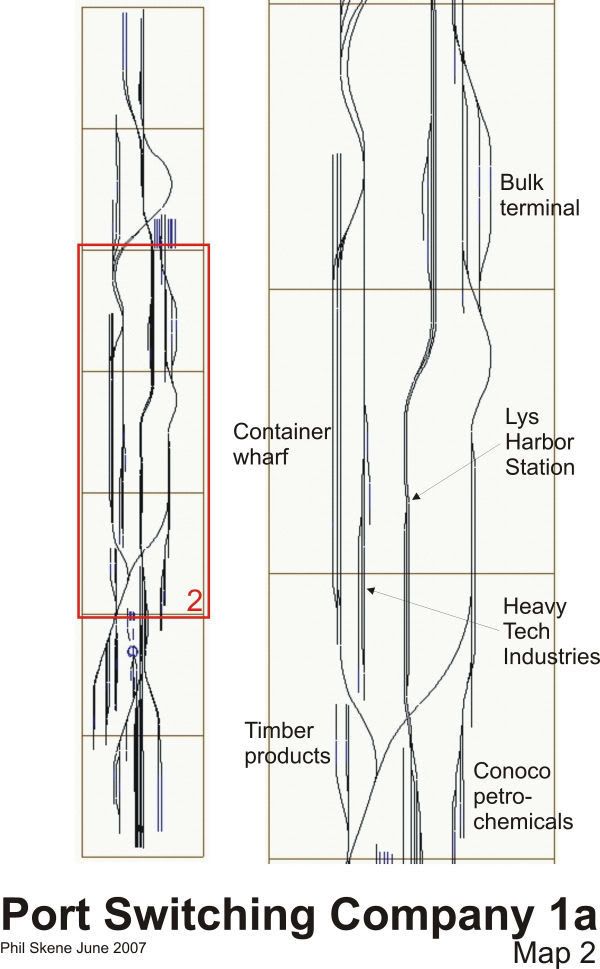

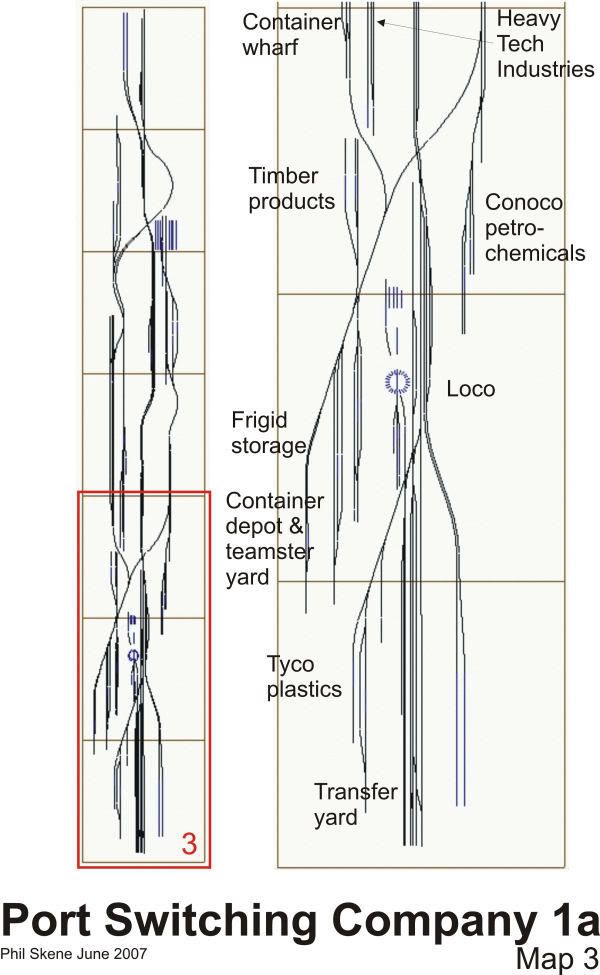

I have devised my first TRS route, a map of which is at

http://users.waymark.net/~mjolnir/AURN_op.jpg

At the beginning of a session, there will be cars received in interchange on the interchange tracks (the tracks to the right of the numeral 3); there may be loads and empties in the yard (the three tracks above and to the right of the numeral 6). Track 5 serves the powerhouse (4), and is where carloads of LP gas are unloaded. The sole customer (located at 11) on the route is a business which receives inbound product in bulk, blends and packages the product into consumer sized packaging. Inbound empty packaging is is received on track to the left of the numeral 9. Inbound loaded tank cars are unloaded on the track just above and to the left of the numeral 7. Inbound hoppers on the track numbered 8. Boxcars are loaded on the two tracks at the top, to the left of the numeral 10.

At the start of a session, there will probably be partially unloaded cars on tracks 5, 7, 8, and 9; there will be loads and empties in the yard, and there may be loads and empties on the interchange tracks. At the beginning of a session, there will be orders from the shipper as to which loads are to be pulled from 10, and which empties are to pulled from 7 and 8, and which cars are to be moved from the yard to the various loading and unloading tracks. Sometimes it will be necessary to move a partially unloaded car to pull the empty behind it, in which case the unloaded car needs to go back to the place it was originally spotted. The order in which cars are delivered to the interchange tracks is important. For interchange deliveries, cars destined to points on the connecting line (in green) to the right need to be grouped separately from cars destined to points on the connecting line to the left, so cars need to be in the proper order.

In the sessions on this route, the instructions will be to pull loads and empties from the plant, to spot empties for loading, and loads for processing, and to pick up and deliver the interchanges. Specific inbound loads will have to be delivered to specific spots. On occasion a car may be delayed, and warrant a special trip to the interchange to get the car as soon as it is delivered, and spot it to the plant.

Now, imagine that this route is included as a subset of a route of the railroad which is represented in green, so that one operates the interchange from the opposite direction. Here, one would only be concerned with pulling loads and empties from the interchange track (3). In this case, your train might have a block of cars in it which get delivered to the interchange, and there might be cars at the interchange which were delivered a couple of days ago (or longer) for you to pull.

ns