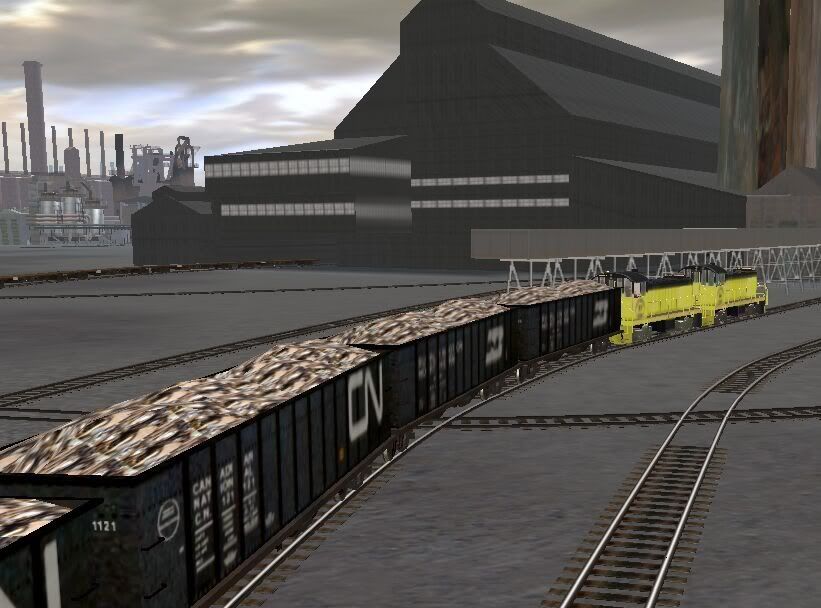

Bethlehem Steel Switcher is DL531

Bethlehem Steel switcher is DL531 made by Wiley4. Search the DLS DL531 Bethlehem Steel.

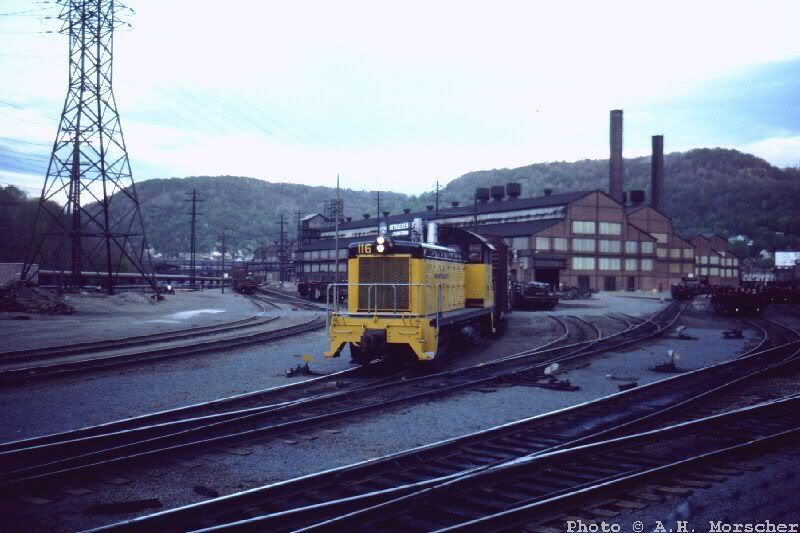

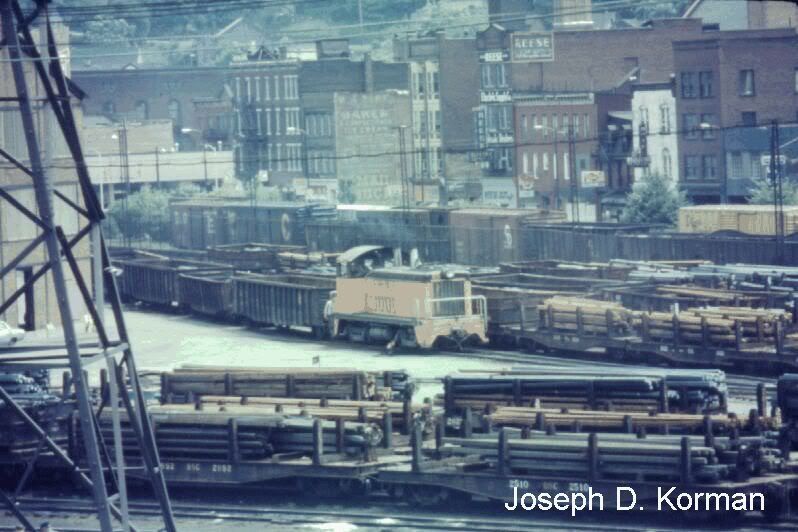

Actually the Conemaugh & Blackick RR used both standard gauge and narrow gauge locos. DLS531 represents the narrow gauge side even though the route done in all standard gauge. Here is an actual picture.

See the narrow gauge loco in the backround.:wave:

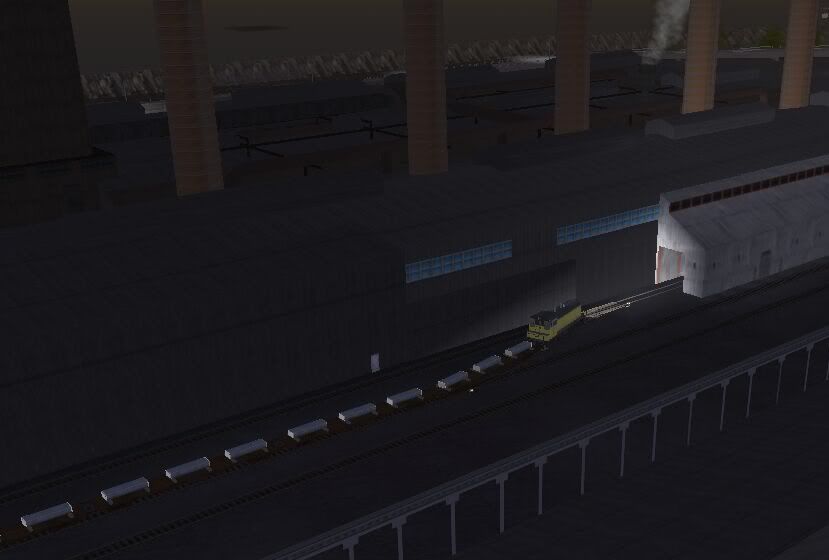

Great shots, and I too love industrial layouts.

Is that Australian thing supposed to be a Baldwin AS616?

Bethlehem Steel switcher is DL531 made by Wiley4. Search the DLS DL531 Bethlehem Steel.

Actually the Conemaugh & Blackick RR used both standard gauge and narrow gauge locos. DLS531 represents the narrow gauge side even though the route done in all standard gauge. Here is an actual picture.

See the narrow gauge loco in the backround.:wave: