Thanks to davesnow, we now have the Thrall and Evans all-door boxcars in Trainz. I have always wondered why these cars were not successful in the U.S.

As far as I have been able to ascertain, these cars were conceived in the 1960s and remained in service until the mid-90s.

The Thrall cars were owned by lumber companies, which used them to carry lumber.

I found images of Evans cars owned by Southern, Southern Pacific, ATSF and Bennet Lumber Products.

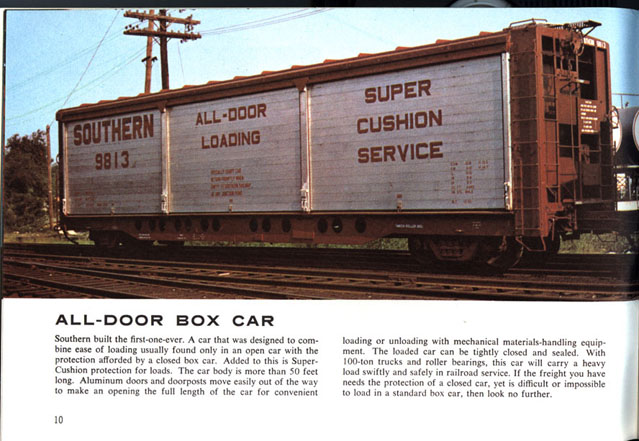

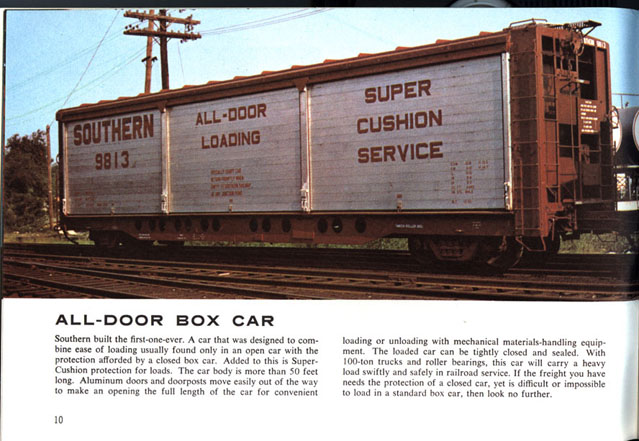

In Europe, all-door cars appeared in the late 1960s and now they have almost completely replaced conventional boxcars for a wide range of loads, such auto parts, paper rolls and almost any conceivable palletized load, since loading/unloading with a fork lift is much easier and faster than a conventional boxcar. These are the features that are highlighted in this description of a Southern prototype built in 1961:

Can someone explain why this type of car has not been successful in the U.S.?

Thanks in advance

As far as I have been able to ascertain, these cars were conceived in the 1960s and remained in service until the mid-90s.

The Thrall cars were owned by lumber companies, which used them to carry lumber.

I found images of Evans cars owned by Southern, Southern Pacific, ATSF and Bennet Lumber Products.

In Europe, all-door cars appeared in the late 1960s and now they have almost completely replaced conventional boxcars for a wide range of loads, such auto parts, paper rolls and almost any conceivable palletized load, since loading/unloading with a fork lift is much easier and faster than a conventional boxcar. These are the features that are highlighted in this description of a Southern prototype built in 1961:

Can someone explain why this type of car has not been successful in the U.S.?

Thanks in advance