Next Step Open Hearth Furnaces

Blast furnaces make hot liquid iron. Open hearth furnaces make steel.

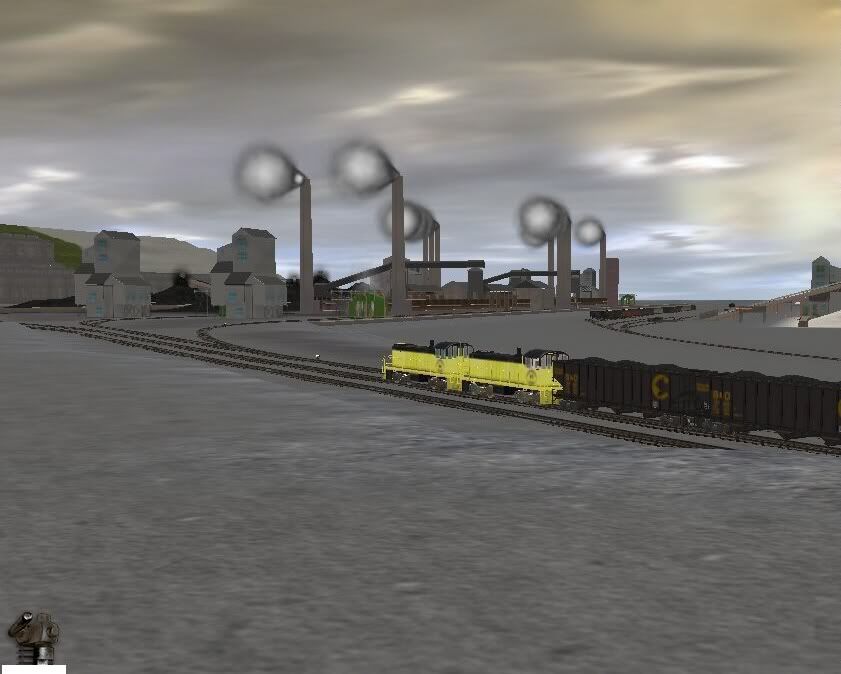

Hot Liquid iron is transported from the blast furnace to the open hearth furnace in torpeto cars.

Load of hot metal leaving H blast furnace (Bethlehem Steel lettered their blast furnaces. My model has E,F,G,H,K,L blast furnaces.)

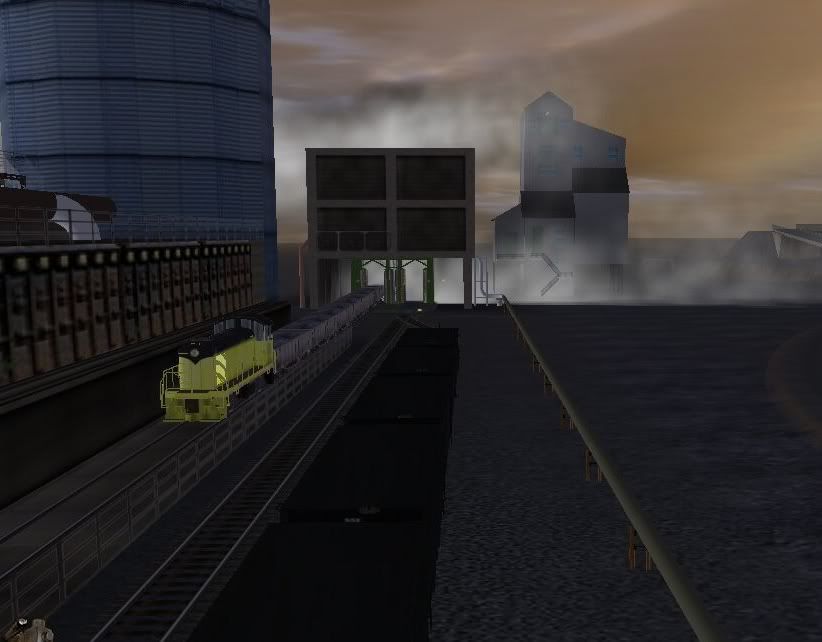

Almost there!

Charging the Open Hearth Furnace with hot metal.

Hot metal from the Blast Furnace is combined with scrap and is heated under temperature controlled conditions usually for at least 6 to 8 hours. Oxygen lances feeding liquid oxygen into the process could speed up the the melt time considerably. Actually Bethlehem Steel had about half of their Johnstown open hearths fitted with oxygen lances which is similar to the more modern Basic Oxygen Furnace (BOF) practice. At this point the chemistry of the steel being made comes into play. There are hundereds of grades of steel with different purposes. I will not attempt to explain that but if you are familar with the Pittsburgh Steelers emblem the blue stands for carbon steel, the yellow for sulfur steel and the red stands for alloy steel.

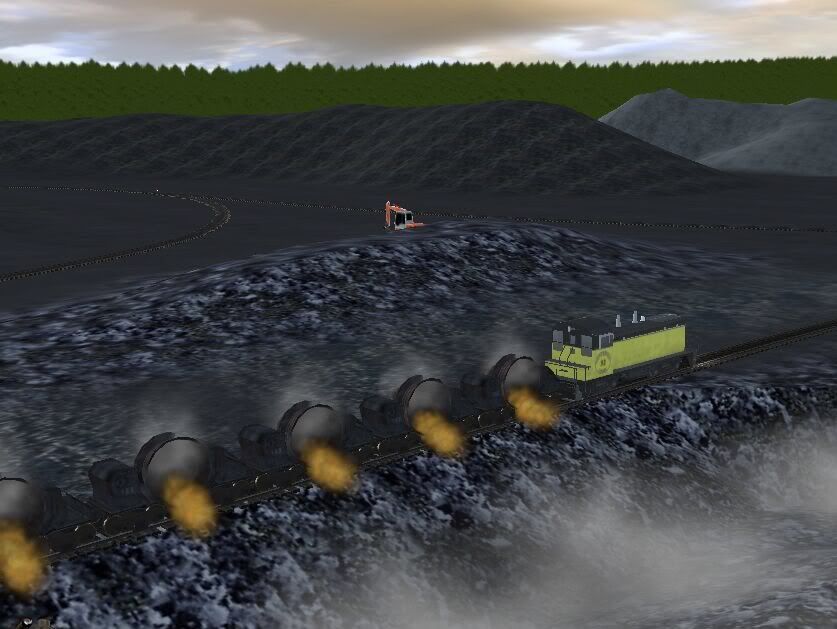

Ingot molds

After the iron is transformed into steel in the open hearth furnace, the furnace is tapped and the liquid steel is poured into ladels. The ladels fill ingot molds shown above this process is called teaming.

The hot ingots are "stripped" of their molds and aloud to cool somewhat. The ingot hardens from the outside in. So the hot ingots go to the soaking pits and are reheated until outside temperature equals the inside temperature.

Apology - This product asset does not exist in Trainz at present.

A shameless plea - oh, Maddy25 please make this, please,please!

The best substitute for "Real" steel ingots are these alumimum ingots shown above.

Next lecture....Scrap

More to Come......:wave: